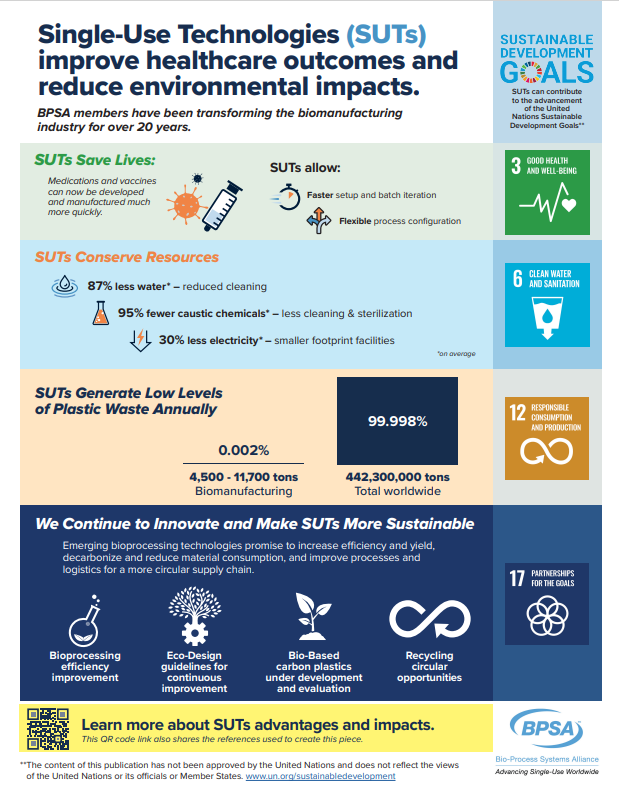

Single-Use Technologies (SUTs) improve healthcare outcomes and reduce environmental impacts.

In 2015, the countries of the United Nations General Assembly adopted the 2030 Agenda for Sustainable Development, which included 17 Sustainable Development Goals (SDGs) across economic, social, and environmental factors. Biopharmaceutical companies are essential in supporting these goals, with SDG 3 Good Health And Well-Being, with targets focused on ending disease epidemics and reducing mortality rates, often being a top priority. Single-use technologies (SUT) support in achieving the SDG 2030 targets by enabling fast development of new drugs and therapies, as seen during the pandemic (1), bringing reproducibility, safety, flexibility, and time efficiency with lower investment (2,3,4).

Healthcare climate footprint contributes to 4,4 % of total global emissions (5). In 2022, seven pharma CEOs announced a new joint initiative to accelerate net zero healthcare (6). SUT is part of the solution in reducing global healthcare emissions. Indeed, it has been demonstrated that in most cases, implementing SUTs helps the biopharmaceutical industry advance towards meeting its environmental targets. SUTs support progress towards resource use optimization, particularly water, energy, emissions, and footprint reduction (2,3,4,8), which contributes to SDG 6 Clean Water And Sanitation and SDG 12 Responsible Consumption And Production. Development of new bioprocess manufacturing methodologies and related technologies such as process intensification, enabled by SUT, also contribute to bioprocess environmental impact reduction (9).

Most SUTs are composed of high-performance plastics, carefully selected and qualified to meet specific application needs. Biopharmaceutical manufacturing related plastic waste is estimated to be less than 0.002% (weight) of global plastic waste (7). Bioprocess utilization of SUT reduces the amount of liquid waste (cleaning water) used in the manufacturing process yet creates solid visible waste. Although the risk of noncontrolled plastic pollution from the biopharma industry is very limited due to regulations (10;11), there is a call for finding better solutions for post-use SUT management.

Despite its added benefits, plastic usage is the subject of controversial social debate in all industries, putting the Plastics Industry under pressure to improve circularity solutions, from material sourcing feedstock (beginning of life) to plastic and plastic packaging post-use management (diversion from incineration and landfill), which could be made applicable to the bioprocess industry. Implementing such solutions in our industry requires a collaborative effort along the value chain, and creation of collaborative networks, such as BPSA, in the spirit of SDG 17, Partnerships For The Goals.

References:

- Dieter Eibl, Regine Eibl, Chemie Ingenieur Technik, volume 94, Issue 12, page 1871 First published: 22 November 2022 https://doi.org/10.1002/cite.202271202

- Flanagan, W., Brown, A., Pietrzykowski, Matthew Pizzi, V., Monge, M., & Sinclair, A. (2011). An Environmental Life Cycle Assessment Comparing Single-Use and Conventional Process Technology. BioPharm International, 2011(8). Retrieved from https://www.biopharminternational.com/view/environmental-life-cycle-assessmentcomparing-single-use-and-conventional-process-technology

- Budzinski, K., Constable, D., D’Aquila, D., Smith, P., Madabhushi, S. R., Whiting, A., Collins, M. (2022). Streamlined life cycle assessment of single use technologies in biopharmaceutical manufacture. New Biotechnology, 68, 28–36. https://doi.org/10.1016/j.nbt.2022.01.002

- Cochet, O., Corbière, J. C., Sinclair, A., Monge, M., Brown, A., & Eschbach, G. (2013). A Sustainable, single-use facility for monoclonal antibody production. BioProcess International, 11(11), 34–40.

- Produced by My Green Lab with contribution from Intercontinental Exchange (ICE). Originally released October 2021, revised and updated with new data and analysis, December 2023.

- Seven pharma CEOs announce new joint action to accelerate net zero healthcare (astrazeneca.com) – (AstraZeneca, GSK, Merck KGaA, Novo Nordisk, Roche, Samsung Biologics and Sanofi)

- In an article to be published in November/December 2024 issue of Pharmaceutical Engineering, the ISPE Disposables/Single-Use Technologies Community of Practice Steering Committee reports biopharmaceutical manufacturing related plastic waste is estimated to be 4,500 metric tons /year for 2023 and 11,700 metric tons /year by 2028. The projected plastic waste generation for all plastics is 389.300 million metric tons for year 2023 and 442.300 million metric tons for year 2028 (Statista, Bruno Alves, November 2020, Global plastic waste generation outlook 2020-2060 | Statista)

- William G. Whitford, Mark A. Petrich, William P. Flanagan, in Environmental Impacts of Single-Use Systems, chapter 13, book Editor(s):Regine Eibl, Dieter Eibl, first published: 26 July 2019 https://doi.org/10.1002/9781119477891.ch13.

- Müller D., Klein L., Lemke J., Schulze M., Kruse T., Saballus M., Matuszczyk J., Kampmann M., Zijlstra G., Process intensification in the biopharma industry: Improving efficiency of protein manufacturing processes from development to production scale using synergistic approaches, Chemical Engineering and Processing – Process Intensification, Volume 171, 2022, 108727, ISSN 0255-2701. https://doi.org/10.1016/j.cep.2021.108727.

- Management of Hazardous Waste Pharmaceuticals (EPA) Management of Hazardous Waste Pharmaceuticals | US EPA

- Waste Framework Directive (European Commission) Waste Framework Directive – European Commission

Download infographic here.

This resource was developed by the BPSA Sustainability Committee. Learn more about BPSA’s committees and technical resources.